Sev-valve's V Port Ball Valve is an application-specific device used in the control of fluids or gas flow. Just think of a ball in a pipe that can rotate. Just spinning this ball opens or closes the flow. What's especially unique about this valve is that the ball contains a V-shaped notch that has been cut into it. That notch allows the valve to make fine adjustments to the flow, just like turning a faucet just slightly to get as much water as you want. The industrial world is the domain of factories and chemical plants that have used this valve due to its superior performance and reliability. Sev-valve v ball valve is used in numerous industries with a variety of benefits.

At first, it is very attractive the V-shaped notch of the ball, since it provides ability to the workers to get the flow exactly. This sev-valve v ball valve is very important when it is applied in a certain place where correct flow matters very much, such as in a restaurant kitchen or a water treatment plant. The second reason is that due to the specific design, this valve is quite strong and tends to resist damage that causes other valves to fail. The design of V Port Ball Valve particularly allows fluid to flow with no friction. Smooth flow prevents wear and tear, meaning the valve can last for a very long time and does not require much replacement. Lastly, the V Port Ball Valve is designed for high-pressure applications, making it appropriate for industries with a high pressure demand, such as oil and gas operations.

The three parts that work together to operate the Sev-valve V Port Ball Valve. The body is the first part of the text. This is the central part of the valve through which the liquid or gas passes and connects to the pipes. The second part is the ball itself that is the piece controlling how much fluid can pass through. The ball can pivot to either open or shut the flow. The third part is called the stem. The stem is that part which lies between the handle and the ball. When the handle is turned the ball too get turned due to aid from the stem, the fluid either allows it to pass through or stop it.

What is more, the V Port Ball Valve has different designs as well. So, for instance, the two way valve has one entry point for the liquid to go in and one opening for it to come out. This design lets the liquid enter and leave freely. However, the three-way valve has three ports with the possibility to reverse the route of the flow. This is useful if you want the liquid to flow into various areas. Also, this sev-valve control ball valve can be manufactured in different sizes based on the application that utilizes them, which makes them extremely versatile.

Maintenance of Sev-valve's V Port Ball Valve is vital for its extended and effective Function. What you should first do is inspect the valve for leaks, cracks, or other signs of potential damages. This is an important step because a malfunctioning valve shows a larger problem ahead. Periodically, the valve must be clean and free from dirt or debris that might stop the flow. Then, if soil gets into the valve, it won't work correctly. Thirdly, you note that the valve is getting dry so you must lubricate it often. It enables the ball to rotate without a hitch, and the valve works correctly. Lastly, ensure that you follow all the installation instructions when fitting the valve correctly. This way, you would have avoided possible damage in case you fitted the valve wrongly.

Sev-valve's V Port Ball Valve can be manufactured in a variety of sizes and materials to fulfill many different applications. They are available in sizes from small (for example, 1/2 inch) to large (as much as 12 inches). That means you can choose the best size for your needs. The sev-valve top entry ball valves can be fabricated from different materials including stainless steel, carbon steel, PVC, and brass. Um, material selection is critical here, and it's a function of factors like the type of fluid, and the temperature and pressure requirements for the application. Stainless steel, for example, is chosen because of its durability and resistance to rusting, while PVC would be appropriate for lighter liquids.

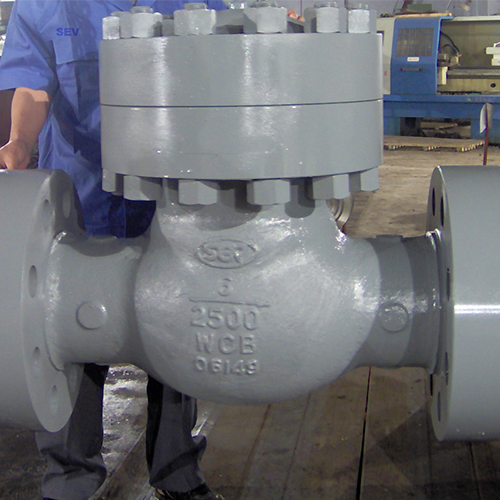

The main products of SEV include ball valves and check valves. Materials include V port ball valve, the CF8, CF8M, CF3, CF3M, LF2 and 304. 316L, 316L, Titanium, Monel, 304L and 316L. LF2, LCB, LCC A105, 316L and 316L. 316L,304L, 304L, 316L Pressure ranges from 150lb to 2500lbs (0.1Mpa-42Mpa) and the sizes are 1/2" up to 48" (DN6-DN1200). SEV is able to manufacture valves for working temperature as low as -196 to 680. These valves are designed, and made in compliance with the standards of ASME, ANSI, API, DIN, JIS etc.

The ability to customize products for clients is a key element in our continuing effort to improve our technology. We offer non-standard valves, V port ball valve, and special industrial items. Based on the requirements of our customers We can supply products that are more durable, safer, and economical.

As a company certified by API6D and ISO9001, SEV is totally committed to providing every customer with V port ball valve products and services can be relied on as well as expert technical guidance they can trust, as well creative supply chain solutions that improve business efficiency and add value. Over many time, we've been able to provide custom-designed products and services to customers from overseas and various high-precision technology companies.

SEV VALVE is a renowned manufacturer of industrial valves. It has all the qualifications necessary to manufacture high-quality industrial valves that can endure the most demanding and rigorous services in the Oil, Gas, V port ball valve, Chemical, Marine, Power and Pipeline Industries. We have long-term, reliable, and cooperative relationships with over 200 manufacturing companies across the globe.

ONLINE

ONLINE