If you are working in the factories or in the plant, you may have heard about v ball valves. They are specialized tools that are essential in regulating the flow of liquids and gases within the capacity of pipes. However, what are v ball valves exactly? In this article, learn the basic features of v ball pigging valves and find out how well they are suited for a variety of types of jobs typically found in the industrial industry

One of great things about v ball valves is their versatility. They are adaptable and can be used in a wide range of scenarios and settings. For instance, they are capable of dealing with a diverse set of temperatures, pressures, and flow rates. It is this quality that makes them ideal for many different job roles in the industrial spectrum. Utilizing v ball stainless steel valves saves money due to high usage control that ensures less energy consumption and waste during the work processes. It allows you to be more judicious and responsible with your resources

V top entry ball valves are also very easy to maintain which is another great feature. In this way, they have fewer moving parts than other types of valves, making them less prone to breakdowns and required repairs. Where service is required it is usually low-hanging fruit like a seal or gasket. So, your systems can continue to run with minimal interruptions thanks to this maintenance ease.

Another feature that is definitely worth paying attention to is the material used to manufacture the valve. V ball valves, as with other types of ball valves can be made from a variety of materials including stainless steel, brass or even plastic. The material selected will depend on what type of liquid or gas you are managing as well as the temperatures and pressures of your specific application. Selecting the appropriate material is crucial to cover the valve's failure to respond to its surroundings.

Overall, v ball valves provide several benefits in industries that require precise control over flow and pressure. They provide accurate and consistent control that can help ensure smooth operation. They are also low-maintenance, saving you both time and money. If you are looking to select a v ball valve, all of the finding, measurement, and designing of the valve is an essential to make sure that you have the right application fit.

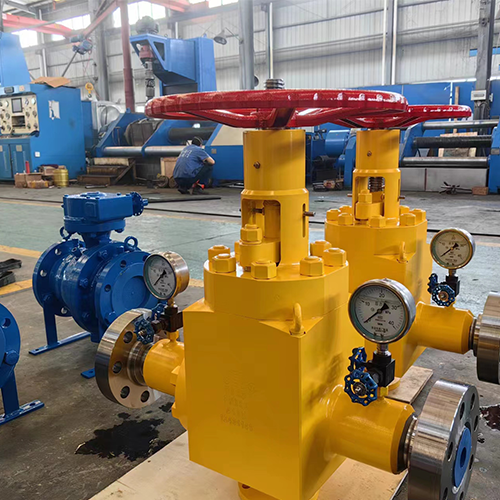

SEVVALVE, is a leading manufacturer of industrial valves from China. It has passed all specifications to produce high-quality industrial valves that can handle the most demanding and severe products of the Oil, V ball valve, Refinery, Chemical, Marine, Power and Pipeline industries. We have built long-term and dependable relations with more than 200 global manufacturers.

V ball valve products for our clients is a key element of our constant quest for technological innovation. We are able to offer non-standard products including clamps, valves and industrial specialties. Based on the needs of our customers, based upon our research and development technologies and design and manufacturing experience for more stable solid, secure, and inexpensive products.

SEV as an enterprise accredited by API6D, V ball valve and other standards We are committed to providing customers the highest quality products as well as skilled technical advice. We also provide innovative supply chain solutions that improve the efficiency of your business.

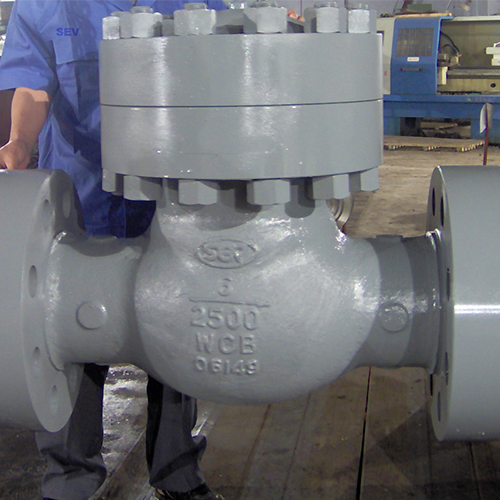

The major products of SEV include ball valves, gate valves, check valves that are made from WCC, WCC and CF8M. V ball valve, CF3M, LCB, LCC, LF2 A105, 304 of 316,304L F51, Titanium and Monel and many more. The range of pressure is 150lbs to 2500lb (0.10Mpa to 42Mpa) and the sizes are 1/2" to 48"(DN6 to DN1200). SEV is able to produce valves with working temperatures of -196 ~ 680. These valves have been designed and produced in accordance with the standards ASME, ANSI API DIN JIS.

ONLINE

ONLINE