The metal seated trunnion ball valves produced by Sev-valve have a quite robust metal inlaid seat which is one of the best feature of these valves. These seats are constructed from hardened materials such as stainless steel and carbon steel. This means they have a long metal seated lifespan and can withstand extremely high temperatures without melting. This is important because, in many jobs, valves are under a lot of pressure. Unlike a soft seated valve, which might break or deform when put under a lot of stress, these metal seats are meant to be durable and long-lasting. They are able to continue functioning even in difficult conditions, which makes them an excellent option.

This is significant because leaks can create issues with the materials being transported and lead to production losses. Your design of valves is inclined to move the ball while keeping seats unmoved. This ingenious design contributes to a snug seal, top entry ball valve preventing leaks and keeping the liquids secure and uncontaminated. Also, the metal seats are viable under various temperatures and pressures. This means that they are capable of a strong seal even in extreme conditions, making it quite important in many industrial applications.

The tough metal chairs were designed to last a lifetime without needing repairs or replacements. This durability is a major benefit since it saves money for the companies. Valve wear—limits wear on valve parts due to special trunnion ball design That top entry ball valves allows the valves to continue to function properly for a very long time, which reduces maintenance costs. Longer-lasting valves equal less machine downtime, which gets more product out the door.

This means that they are designed for durability in the most demanding of settings. Moreover, they can be tailored to fit axial flow check valve the requirements and standards of a certain industry. Their adaptability makes them perfect for many jobs, available to work through different scenarios.

They also tolerate harsh working environments and can be tailored for varying types of jobs. Choosing Sev-valve's metal axial flow check valves seated trunnion ball valves means that customers will be able to benefit from quality valves that operate well over a long lifespan. It allows them to work without worrying about valve issues.

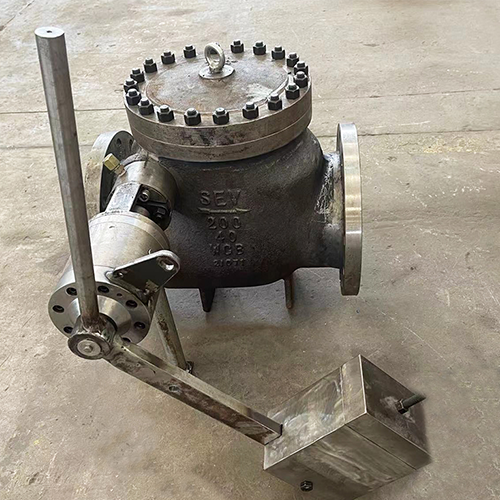

As an organization accredited by API6D and ISO9001, SEV is totally dedicated to providing each customer with products and services can be relied on; specialist technical advice they can trust, as well creative supply chain solutions that boost efficiency in business and create value. Over the time, we've offered tailored products and services for foreign customers Metal seated trunnion ball valve as a variety of high-precision technology firms.

SEV VALVE, is an excellent manufactory of industrial valves from China. It has Metal seated trunnion ball valve all prerequisites to manufacture reliable industrial valves for the most extreme and demanding services offered by the Oil, Gas, Refinery, Chemical, Marine, Power and Pipeline industries. We have established long-term and dependable relationships with over 200 global manufacturers.

The main products of SEV include ball valves and Metal seated trunnion ball valve. Materials include WCB CF8, CF8M, CF3, CF3M, LF2, 304, 316L, 316L, Titanium, Monel, 304L and 316L. LF2, LCB, LCC, A105, 316L, 316L, 304L, 316L and 304L. The pressure range is 150lb to 2500lb (0.10Mpa up to 42Mpa) and the sizes range from 1/2" to 48"(DN6 to DN1200). SEV can manufacture valves that have a working temperatures of between -196 and 680. These valves are designed and made in compliance with the specifications of ASME, ANSI, API, DIN, JIS etc.

Our ongoing pursuit of technological innovations includes providing customized products to our clients. We are able to offer Metal seated trunnion ball valve like clamps, valves, industrial specialties and so on. We can customize our products to meet the requirements of our clients, based on our own research and development technologies as well as our design and manufacturing expertise, to provide more stable, reliable, safe and cost-effective products.

ONLINE

ONLINE