Axial Flow Check Valves are dams and tanks that allow liquids to only move in one direction. That is a very important job as it enables them to be one way and close to stop the other. A key use case for this function is to ensure the free flow of fluids in pipes and other systems, where it is desirable. In the absence of these valves, liquida could flow backward that lead to trouble in system.

Parts Of An Axial Flow Check ValveDifferent parts come together to make an axial flow check valve and control the movement of liquids. The valve body is the primary part of a sanitary valve. The valve body links with the pipes for a particular fluid system, allowing to create the stronger connection between valves and liquid flow. There is also another disk on the valve body which opens and shuts to allow liquids pass from one way but prevent them returning. The disk is crucial because it makes sure the flow stays at a nominal value.

Because our next valves are so important, To start, they make sure that certain fluids go where they need to throughout the system. These valves also work to prevent the backflow and maintain pressure or flow conditions in that system for it to operate as desired. That has a number of effects, not just on the pumping efficiency at that station or what have you, but also if pressure dropped in the system because we had this increasing backflow situation - let's say protection one wasn't working for some reason and there was fuel coming out over here when they wanted it either in storage tank A or going into engine B.

But there are also some disadvantage of these valves. The most problematic issues to date have been their dirt sensitivity as well other small fouling particles which may be present in the liquid. If these particles block the valve, then they can stop it from closing fully. This could result in backflow that would cause the system to be damaged and lose its effectiveness. These issues can be avoided with regular cleaning and maintenance.

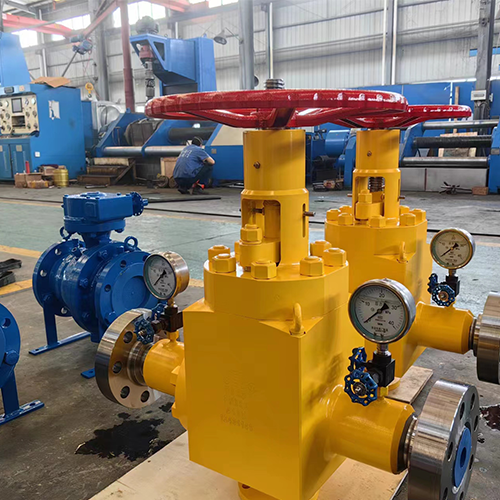

IntroductionAxial flow check valves are designed for a wide range of applications, but they are vital to the oil and natural gas industries. They are liquid-intensive industries, and therefore have been developed around large systems designed with the extraction, transport and processing of fossil fuels in mind. These axial-flow check valves are instrumental in the effort to sustain pressure and flow rates which are required for any fluids that need be moved down lines. The systems could have huge problems without those valves.

Axial flow check valves find application not only in the oil and gas industries, but many other domains as well. Industrially, they are used in chemical processing, water treatment and power generation. These valves are used in all these industries to make sure that the liquids move freely and smoothly from one system t another. They are an essential part of maintaining the smooth functioning between operations.

Troubleshooting can help you identify the reason that the valve is not working properly in case of a defective solenoid. An axial flow check valve is a type of directional safety device that is prone to certain issues, such as leaking and intermittent backflow. Most cases can be fixed with valve cleaning, the replacement of minorly broken parts or alterations in presssure and flow rate systems to guarantee all works fine.

Our continuous pursuit of technological innovations includes providing axial flow check valves to our clients. We offer products that are not standard including clamps, valves and industrial products. Based on the needs of our customers, based on our own research and development technology as well as our design and manufacturing expertise to offer more durable as well as safe, reliable and affordable products.

As an organization certified by API6D and ISO9001, SEV is totally committed to providing every customer with high quality products and services can trust and receive expert technical advice that they trust as well innovative supply chain solutions which increase efficiency for businesses and add value. Over many time, we've provided tailored products and services for customers from overseas and various axial flow check valves.

axial flow check valves is a world-class manufacturer of industrial valves. It has the necessary qualifications required to make sturdy industrial valves that will endure the most demanding and rigorous services in the Oil, Gas, Refinery, Chemical, Marine, Power and Pipeline Industries. We have long-term, reliable and collaborative relationships with over 200 manufactures around the world.

The main products of SEV include ball valves and axial flow check valves. Materials include WCB CF8, CF8M, CF3, CF3M, LF2, 304, 316L, 316L, Titanium, Monel, 304L and 316L. LF2, LCB, LCC, A105, 316L, 316L, 304L, 316L and 304L. The pressure range is 150lb to 2500lb (0.10Mpa up to 42Mpa) and the sizes range from 1/2" to 48"(DN6 to DN1200). SEV can manufacture valves that have a working temperatures of between -196 and 680. These valves are designed and made in compliance with the specifications of ASME, ANSI, API, DIN, JIS etc.

ONLINE

ONLINE