Within this hole, a stem emerges, which is attached to a handle you can turn. When you twist the handle, it moves the stem that top entry ball valves moves the valve’s ball inside.

Dig a hole that is deep enough for a valve—usually at least 12 inches— to sit in it. Once you have dug the hole, gently insert the valve into the hole and connect it to the existing incoming and outgoing pipes. Once completed, backfill the hole with dirt, ensure the valve metal seated is properly secured and of course in place.

A valve that is either too large or too small may not operate efficiently. Secondly, always remember to turn off the valve when you are working in your system. To prevent any blowouts or leaks by water. Third, if you notice any leaks or valve problems, it is very important to act immediately. Resolving issues quickly means avoiding bigger problems down the line. Finally, if you are not experienced with flow check valve the installation of valves, it's probably best to have the valve professionally installed. This way you can save some time and make sure that the valve is properly installed.

Second, these valves are designed to be rugged and long-lasting; hence, their long life. And because you won’t have to replace them often, their durability makes them a long-term cost-effective solution. Third, if the valve is below ground, it is not as susceptible to metal seat harsh weather or other outside damage. This adds to its reliability. Well, of course, one of the most significant benefits of using this type of valve is the fact that it can help you prevent leaks in your system or water damage, which would save a ton of money and headaches down the line.

Second, look in the valve at the ball. You would have to replace the ball if it is stuck or damaged to the extent that it does not function top entry ball valve anymore. Lastly, inspect for leaks or other problems in the pipes surrounding the valve. If there are any leaks or issues, it is extremely critical to correct them immediately. Resolve these problems quickly to prevent more damage and ensure your irrigation system runs smoothly.

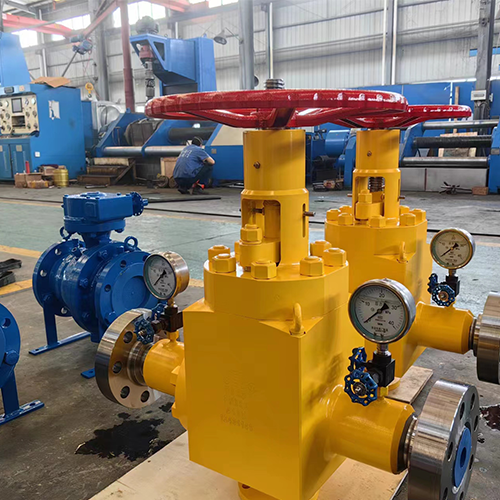

The main products of SEV include ball valves and Underground ball valve. Materials include WCB CF8, CF8M, CF3, CF3M, LF2, 304, 316L, 316L, Titanium, Monel, 304L and 316L. LF2, LCB, LCC, A105, 316L, 316L, 304L, 316L and 304L. The pressure range is 150lb to 2500lb (0.10Mpa up to 42Mpa) and the sizes range from 1/2" to 48"(DN6 to DN1200). SEV can manufacture valves that have a working temperatures of between -196 and 680. These valves are designed and made in compliance with the specifications of ASME, ANSI, API, DIN, JIS etc.

SEV VALVE, is an outstanding manufacturer of industrial valves from China. It is equipped with the skills required to make robust industrial valves that are able to withstand the most demanding and demanding services in the Underground ball valve, Gas, Refinery, Chemical, Marine, Power and Pipeline Industries. We have long-term, reliable and co-operative relationships with over 200 manufactures around the world.

The ability to customize products for clients is a key element in our continuing effort to improve our technology. We offer non-standard valves, Underground ball valve, and special industrial items. Based on the requirements of our customers We can supply products that are more durable, safer, and economical.

As an organization certified by API6D and ISO9001, SEV is totally committed to providing every customer with high quality products and services can trust and receive expert technical advice that they trust as well innovative supply chain solutions which increase efficiency for businesses and add value. Over many time, we've provided tailored products and services for customers from overseas and various Underground ball valve.

ONLINE

ONLINE