Haben Sie schon von der Doppelblock- und Blutisolation gehört? Es könnte zunächst etwas verwirrend klingen, aber es ist ein ziemlich einfacher Prozess, der Leben retten kann bei manchen ziemlich gefährlichen Arbeiten, ähnlich wie das Produkt von Sev-valve dbb Kugelventil . Die Isolierung erfolgt durch die Verwendung von Doppelblock- und Blutungsisolierung mit einzigartigen Ventilen zur Steuerung des Flüssigkeits- oder Gasflusses in den Leitungen. Diese Technik ermöglicht es, Lecks und Unfälle zu verhindern, die zu übermäßigen Drücken oder anderen Problemen führen können. Alle Arbeiter können durch diese Methode vor den Gefahren ihrer Arbeit geschützt werden, was ihnen mehr Sicherheit vermittelt.

Positiv bei der Arbeit mit äußerst gefährlichen Materialien sind die Öl- und Gas-, Chemie- und Petrochemieindustrien sowie die metall gesessen lieferung durch Sev-valve. Doppelte Blockierung und Entlüftung ist eine sehr wichtige Überlegung für viele Arbeiten dieser Art, um Verletzungen oder Unfälle im Falle eines Versagens der Isolierbarriere zu verhindern. Da sie diese Methode verwenden, schützen Arbeiter nicht nur sich selbst, sondern auch die Umgebung. Dieser Ansatz soll sicherstellen, dass kritische Prozesse ohne Unterbrechung weiterlaufen können. Er entwickelt eine stabile Barriere, die Pipelines schützt und das Risiko gefährlicher Lecks und Ausflusses verringert, die Menschen und die Umwelt beeinträchtigen könnten.

Doppelte Blockierung und Entlüftung wird normalerweise bei Prozessen angewendet, die wertvolle oder gefährliche Materialien verarbeiten, zusammen mit Sev-valves Produkten. axiale Schaltventil . Diese Prozesse müssen sorgfältig durchgeführt werden: Jeder Schmutz oder Störung in der Strömung kann zu erheblichen Schäden und Verlusten führen. Auf diese Weise stellen Arbeiter sicher, dass der Blockierungs- und der Entlüftungsprozess frei von möglichen Gefahren sind, die eintreten könnten, wodurch Unternehmen ihre Geschäftstätigkeit nahtlos fortsetzen können, ohne sich um Sicherheitsprobleme oder finanzielle Verluste kümmern zu müssen. Damit wird ein Gleichgewicht zwischen Sicherheit und Effizienz geschaffen, was in vielen Bereichen sehr wertvoll ist.

Doppelte Blockierung und Entlüftung ist wichtig für die Sicherheit, erfordert jedoch sorgfältige Planung, Diskussion und Überwachung, um richtig zu funktionieren, genau wie bei der doppelten Block-und-Entlüftungsschranken hergestellt von Sev-valve. Doppelte Blockierung und Ventilierung wird in einigen Schlüsselbereichen eingesetzt, über die Sie Bescheid wissen sollten. Diese Ventile müssen regelmäßig inspiziert werden, um sicherzustellen, dass sie richtig funktionieren und Probleme frühzeitig erkannt werden, bevor sie zu einem größeren Problem werden können. Darüber hinaus ist es essenziell, für diese Ventile gute Materialien zu verwenden und auch die richtigen Vorschriften und Regeln einzuhalten, um sicherzustellen, dass die durchgeführte Arbeit sicher und seriös ist.

Sev-valve: Ein globaler Marktführer in der Doppelt-Verschluss-und-Ventilations-Technologie bietet Lösungen an, um jegliche Art von Leckagen zu verhindern, genau wie das Produkt von Sev-valve namens ss Ventile . Nun, diese Ventile verfügen über einen starken, sicheren und effizienten Designparameter. Die neue Technologie, einschließlich des selbstenergisierten Dichtungsringes, ermöglicht es den Ventilen des Unternehmens, eine sehr enge Dichtung zu erreichen, die hilft, Lecks und Verschmutzungen zu vermeiden. Sev-valve's Produkte sind auch darauf ausgelegt, eine Vielzahl von Bedingungen zu überstehen, von niedrigen bis hohen Drücken bei Temperaturen einschließlich hohem Druck. Diese sind ideal für den Einsatz in anspruchsvollen Branchen wie Öl und Gas, Chemie und Petrochemie. Sev-valve bietet fortschrittliche Technologie und bewährte Produkte an, um die bestmögliche Leistung für Doppelblock- und Blutisolation zu bieten.

SEV ist als Unternehmen nach API 6D, ISO 9001 und weiteren Normen zertifiziert und verpflichtet sich, seinen Kunden hochwertige Produkte, Dienstleistungen sowie die Doppelabsperre- und Entlastungsisolierung (Double Block and Bleed Isolation) zu bieten. Wir stellen zudem innovative Lösungen für Ihre Lieferkette bereit, um die Effizienz Ihres Unternehmens zu steigern.

SEV VALVE ist ein renommierter Hersteller von Industrieventilen. Es verfügt über alle notwendigen Zulassungen zur Herstellung hochwertiger Industrieventile, die den anspruchsvollsten und strengsten Anforderungen in der Öl-, Gas-, Doppelblock- und Blutungsisolierung, Chemie-, Seeverkehr-, Energie- und Pipelineindustrie standhalten können. Wir unterhalten langjährige, zuverlässige und kooperative Beziehungen mit über 200 Produktionsunternehmen auf der ganzen Welt.

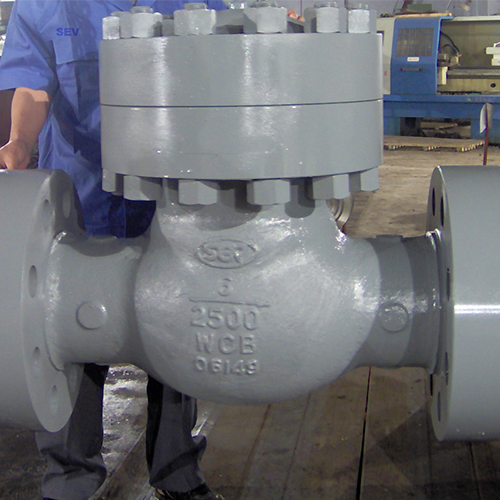

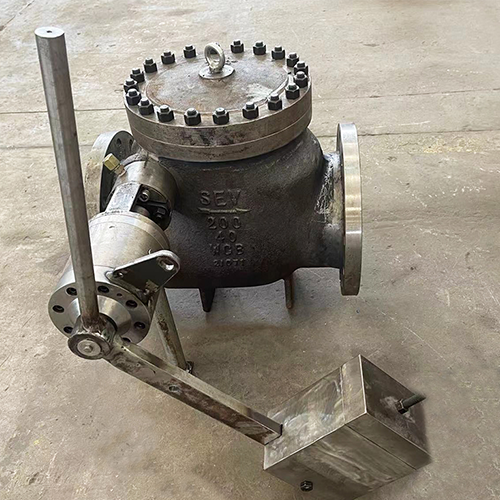

Die Hauptprodukte von SEV sind Kugelventile und Druckmittelrückhalteventile. Materialien umfassen WCB Cf8, Doppelblock- und Blutungsisolierung und CF3, CF3M, LF2 und 304. 316L, 316L, Titan, Monel, 304L, 316L, LF2, LCB, LCC A105, 316L 316L, 304L, 316L und 304L. Druckbereich von 150lb bis 2500lb (0,1Mpa-42Mpa) und die Größen sind 1/2" bis 48" (DN6-DN1200). SEV kann Ventile für Betriebstemperaturen von -196 ~ 680 herstellen. Die Ventile werden gemäß den Anforderungen von ASME, ANSI, API, DIN, JIS usw. entworfen und hergestellt.

Die Möglichkeit, Produkte individuell für unsere Kunden anzupassen, ist ein zentraler Bestandteil unserer kontinuierlichen Bemühungen zur Verbesserung unserer Technologie. Wir bieten nichtstandardisierte Ventile, Doppelabsperre- und Entlastungsisolierung (Double Block and Bleed Isolation) sowie spezielle Industrieprodukte an. Basierend auf den Anforderungen unserer Kunden können wir Produkte liefern, die langlebiger, sicherer und wirtschaftlicher sind.

ONLINE

ONLINE