Do you know about the automatic ball valve? It is a critical component of many machines and systems, such as water treatment facilities and oil refineries. Automatic ball valves are used in these facilities to enhance the control of liquids and gas. Sev-valve is professional automatic ball valve manufacturer and we have high-quality automatic ball valves known for reliable, efficient and easy to use. These orbit ball valve ensure smooth functioning across various industries.

Automatic Ball valve is a unique mechanical valve which also works as a valve that controls the flow of liquid or gas. It operates by rotating a ball-shaped valve which sits within a pipe. As the valve is turned, the ball rotates around to open or close the flow of the liquid or gas. Which means that at the point where you want the flow to begin, the ball turns to open the way. When you need to control the flow, the ball turns and closes it. In industrial fields, this type of valve is most practical and used since they can withstand much higher temperature and pressure without breaking. And it doesn’t require much maintenance, which makes it very user-friendly.

Auto ball valve is composed of several essential components. The ball valve metal body, the ball, the stem, and the actuator are the constituent parts. The valve body is the larger enclosure that contains everything. It ensures all those components are protected and secure. It has a round ball-shaped body and function can stop the flow of liquid for gas. It is like a door that can open and shut. It consists of a long stick called a stem that connects the ball to an alternate part known as an actuator. The element that moves the stem and turns the ball to open or close the valve is the actuator. All of these components work together to ensure proper and efficient operation of the valve.

There are several varieties of automatic ball valves, and each variety has its own unique features. A 2-way valve has an inlet and an outlet, the inlet is where the liquid or gas to be controlled, comes in, the outlet is where it exits. This type of valve is the most basic arrangement. A twin ball valve has three openings that can have the liquid or gas running through it in ways that it can be redirected. This means flows can travel in one of two directions, or they can be mixed together. A 4-way valve with four ports mixes or divides the flow. Depending on what is needed in a specific situation, each type of valve serves different purposes.

Since the Sev-valve automatic ball valve can absorb a very high-pressure ball for their own ball valve types. This makes it ideal for utilization in water treatment plants, oil refineries and other industrial operations where tough and extreme situations are common. Aesthetically pleasing is another great advantage because upkeep is minimal, which saves time and energy. The automatic ball valve teflon seat, unlike other ball valves that can rust or get clogged, is self-cleaning and self-lubricating, which makes it ideal for applications where regular maintenance is not an option. This allows it to maintain itself without needing much maintenance from workers.

Automatic carbon steel ball valve is widely used in various usages. It assists the flow of the water in treatment plants as it goes through different stages of treatment. This is vital to guarantee the purity and portability of the water. At oil refineries, it is used to control the flow of oil and gas as they pass through the pipes. This ensures that nothing goes wrong and no one gets hurt. For example, in chemical plants, it regulates the flow of many chemicals, key for producing different products. Sev-valve automatic ball values are the best suitable for the various industrial need and also help to keep the businesses in a working state.

SEVVALVE is a Automatic ball valve of industrial valves. It is a top-quality company with all the capabilities required to make reliable industrial valves that can withstand the most demanding and demanding services in the Oil, Gas, Refinery, Chemical, Marine, Power, and Pipeline Industries. We have long-term, reliable, and mutually beneficial relationships with more than 200 companies around the world.

Customizing products for our Automatic ball valve is an important part of our constant quest for technological innovation. We offer non-standard valves and clamps as well as special industrial items. Based on the needs of the customers, we have based our products upon our research and development technology and experience in design and manufacturing, to provide more stable secure, reliable, and low-cost unconventional products.

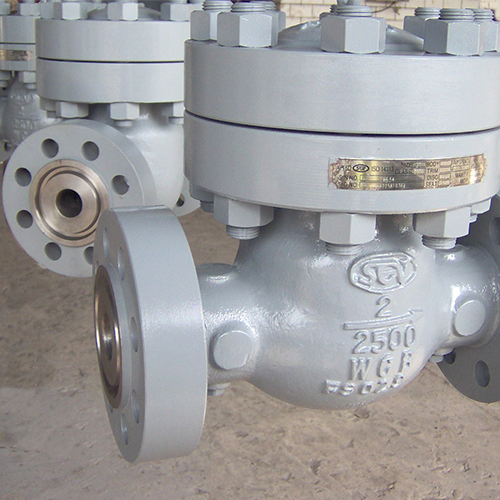

SEV's main products are ball valves as well as check valves. Materials include WCB Cf8, CF8M and CF3, CF3M, LF2 and 304. the 316L, 316L Automatic ball valve, Monel, 304L, 316L LF2, LCB, LCC A105, 316L 356L, 316L and 304L. The pressure range is 150lb to 2500lbs (0.1Mpa-42Mpa) The size is 1/2" up to 48" (DN6-DN1200). SEV can produce valves with a working temperature of between -196 and 680. These valves are designed, and made in compliance with the specifications of ASME, ANSI, API, DIN, JIS etc.

SEV as an enterprise certified under API6D, ISO9001 and other standards We are committed to providing customers top quality products along with expert technical advice. We also offer Automatic ball valve that increase the efficiency of your business.

ONLINE

ONLINE